Our Story

We have been making quality art materials for over 80 years since our founding in 1937 as a manufacturer of dustless chalks. Our chalk products began as regular hard white chalks made from calcium carbonate and were the preferred brand for many schools and businesses. In 1967 we expanded our production and added a factory in Bibai-shi, Hokkaido. Bibai-shi, which translates to, “beautiful shell city,” actually had massive waste piles of scallop shells that were causing serious environmental issues. It seemed only natural to reduce, reuse and recycle this material. With the help of local government we developed a patented process to recycle these shell byproducts. The use of powdered shells had the additional benefit of making Kitpas Chalks stronger, smoother, and longer lasting! It’s no surprise that more than 60% of the chalks currently used by schools in Japan are Kitpas Chalks.

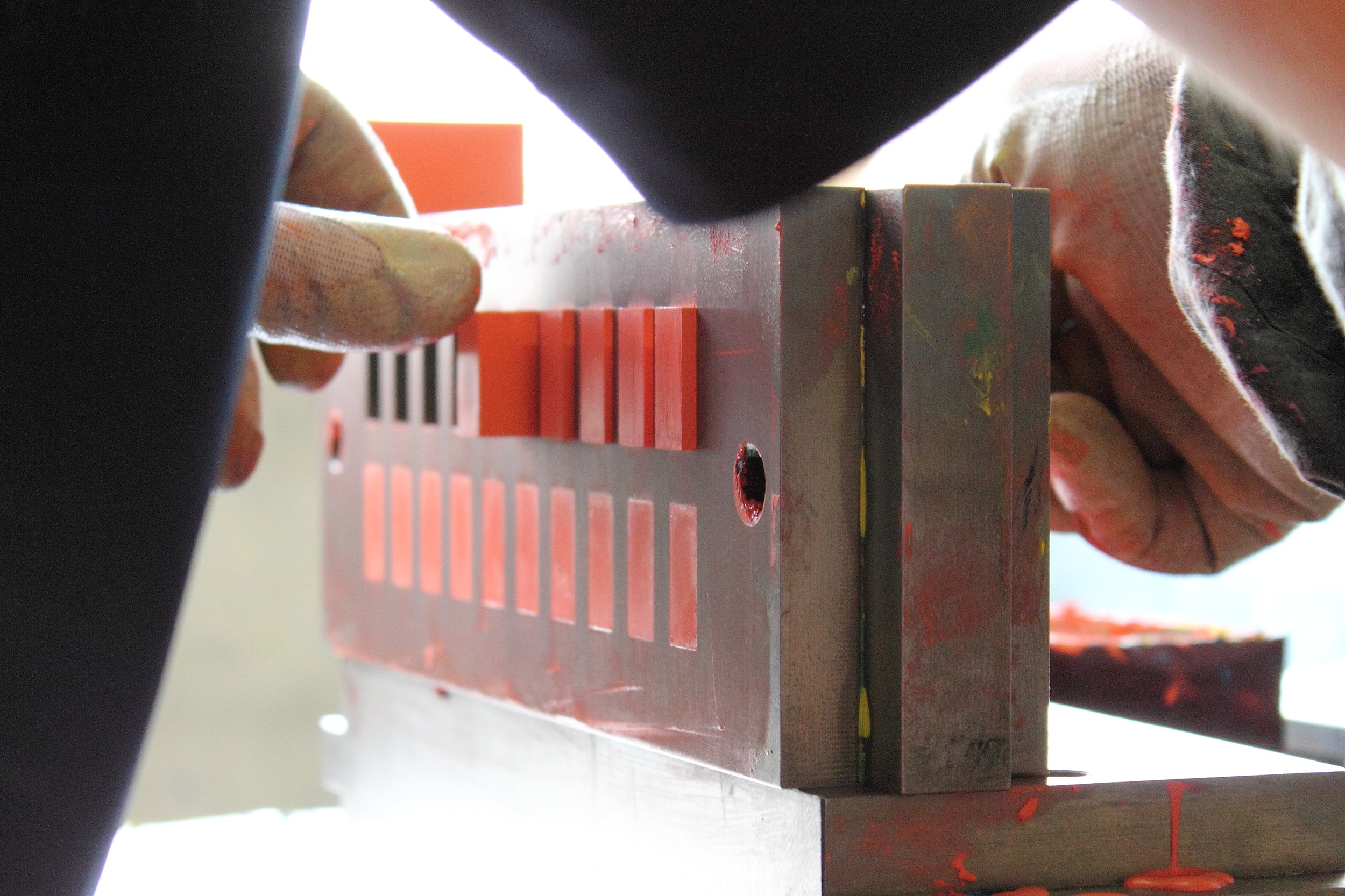

As we continued our product development, we explored ideas for an innovative material that works on surfaces like paper, glass, mirrors and whiteboards. In 2005 we introduced buttery smooth, truly multi-surface, vividly colored and water soluble Kitpas Art Crayons which are also completely non-toxic and easy to clean up. They soon became both kids' and parents' favorite choice of crayons, winning Japan’s prestigious “Stationary of the Year Award” in 2009.

Today, Kitpas has evolved into Japan's leading manufacturer of innovative, eco-friendly art materials. We know you will love our products - let your creativity flow with Kitpas!

Our Values and Commitment to Workers with Disabilities